Public Resources

Public Resources

Physical Considerations for PPE OPerations

A. Stamina and Anaerobic Capacity

Operations involving work in a hazardous materials environment or even in a simulated training environment produces a significant strain on the cardiovascular system. Therefore, any worker designated to work under these conditions should be in good physical shape and should have passed a baseline medical examination. Stamina and anaerobic capacity is necessary in order to endure the naturally increased heart rate and overheating produced by the human body under such extreme physical requirements.

B. Psychological Conditions

Claustrophobia is a phenomenon typically classified as an anxiety disorder that can affect individuals working in confined spaces. Claustrophobic episodes often result in panic attacks. A panic attack during real-world hazardous materials operations could have catastrophic effects. A worker suffering from claustrophobia related to wearing PPE will either feel as though they are suffocating from a lack of oxygen, or that they are confined by the chemical protective suit and/or respirator.

All efforts should be made to test a worker’s capability to perform PPE operations under stressful conditions in order to gauge whether or not that worker is susceptible to or likely to have claustrophobic episodes. You should evaluate an employee’s fitness to wear PPE in a stressful environment. If the worker shows signs of being uncomfortable in the PPE ensemble during training or during exercises, their participation in operations requiring PPE should be reevaluated.

C. Medical Screening and Monitoring Requirements

OSHA has developed specific guidelines for various organizations regarding the health and safety of their employees who will wear respirators in the course of their duties. These guidelines can be found in OSHA Standards 29 CFR 1910.120 and 1910.132, which mandates that hazardous materials team members are both medically evaluated prior to their wearing a respirator, and then medically screened prior to actual operations. Medical monitoring is actually a four step process conducted over a period of time, not simply taking someone’s blood pressure and pulse prior to a hazardous materials event. While this is a critical requirement in the overall process, it is not part of the four-step process. The four step process includes a baseline physical prior to joining the team/program, annual physicals and an exit physical when the member leaves the team/program. If the team member was ever exposed to hazardous materials in the course of their duties, specific physicals or follow up exams may be necessary.

Importance of Medical Evaluations

View the video for a better understanding of why medical evaluations are a critical piece of any respiratory fit protection program.

OSHA Medical Evaluations for Workers Who Wear Respirators

OSHA Respirator Medical Evaluation Questionnaire

Click here for a free copy of a medical evaluation questionnaire.

Source: OSHA

OSHA Sample Donning Procedures - source

- Inspect clothing and respiratory equipment before donning (see Paragraph on Inspection).

- Adjust hard hat or headpiece if worn, to fit user's head.

- Open back closure used to change air tank (if suit has one) before donning suit.

- Standing or sitting, step into the legs of the suit; ensure proper placement of the feet within the suit; then gather the suit around the waist.

- Put on chemical-resistant safety boots over the feet of the suit. Tape the leg cuff over the tops of the boots. If additional chemical-resistant safety boots are required, put these on now. Some one-piece suits have heavy-soled protective feet. With these suits, wear short, chemical resistant safety boots inside the suit.

- Put on air tank and harness assembly of the SCBA. Don the facepiece and adjust it to be secure, but comfortable. Do not connect the breathing hose. Open valve on air tank.

- Perform negative and positive respirator facepiece seal test procedures. To conduct a negative-pressure test, close the inlet part with the palm of the hand or squeeze the breathing tube so it does not pass air, and gently inhale for about 10 seconds. Any inward rushing of air indicates a poor fit. Note that a leaking facepiece may be drawn tightly to the face to form a good seal, giving a false indication of adequate fit. To conduct a positive-pressure test, gently exhale while covering the exhalation valve to ensure that a positive pressure can be built up. Failure to build a positive pressure indicates a poor fit.

- Depending on type of suit: Put on long-sleeved inner gloves (similar to surgical gloves). Secure gloves to sleeves, for suits with detachable gloves (if not done prior to entering the suit). Additional overgloves, worn over attached suit gloves, may be donned later.

- Put sleeves of suit over arms as assistant pulls suit up and over the SCBA. Have assistant adjust suit around SCBA and shoulders to ensure unrestricted motion.

- Put on hard hat, if needed.

- Raise hood over head carefully so as not to disrupt face seal of SCBA mask. Adjust hood to give satisfactory comfort.

- Begin to secure the suit by closing all fasteners on opening until there is only adequate room to connect the breathing hose. Secure all belts and/or adjustable leg, head, and waistbands.

- Connect the breathing hose while opening the main valve.

- Have assistant first ensure that wearer is breathing properly and then make final closure of the suit.

- Have assistant check all closures.

- Have assistant observe the wearer for a period of time to ensure that the wearer is comfortable, psychologically stable, and that the equipment is functioning properly.

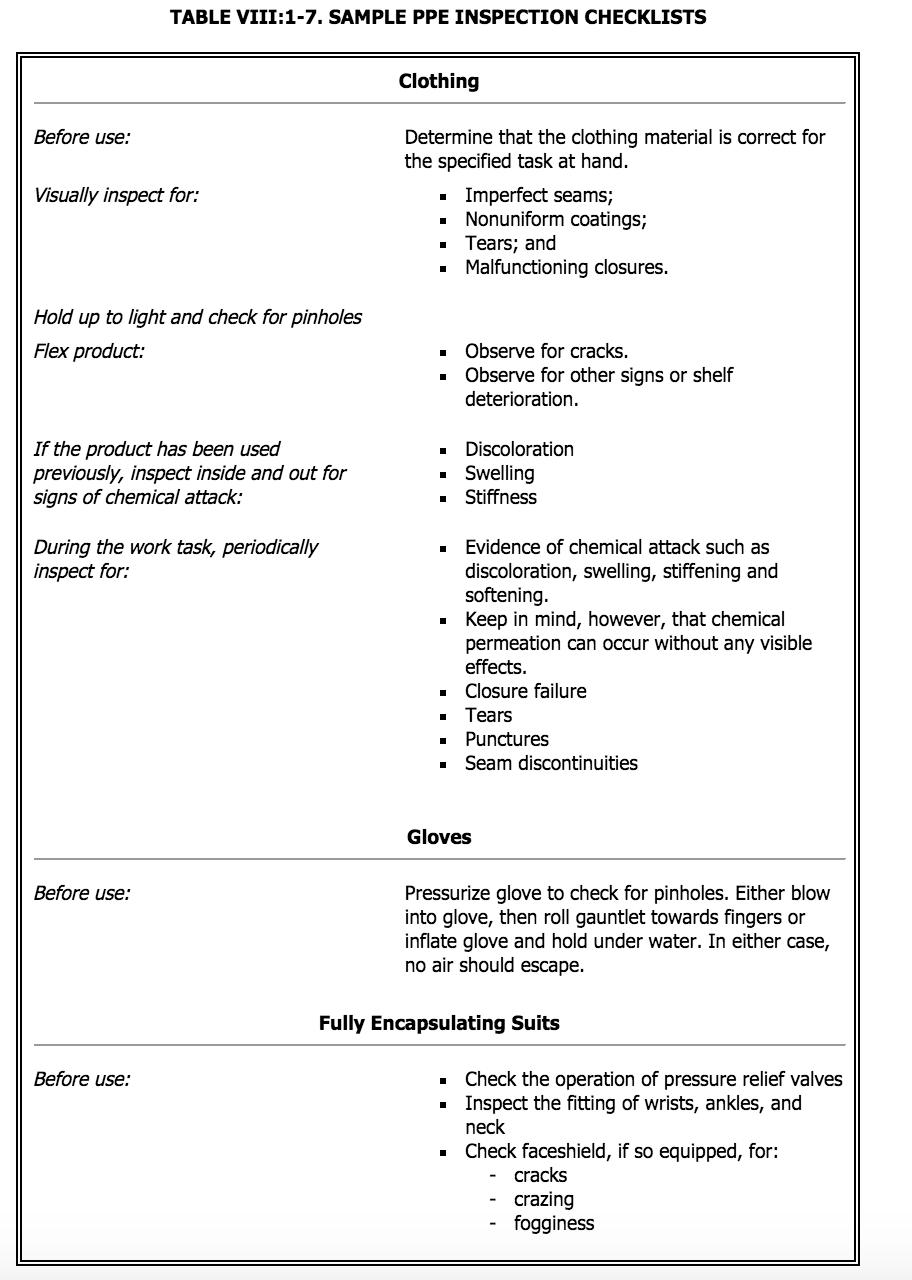

OSHA Sample PPE Inspection Checklists - Source and text versions

« Previous | Topic Home | Next »